Cost Effective Lift Maintenance Repair: Maintaining Your Lifts Running Efficiently

Cost Effective Lift Maintenance Repair: Maintaining Your Lifts Running Efficiently

Blog Article

The Total Manual to Raise Maintenance: Keeping Your System Running Efficiently

In the realm of structure maintenance, guaranteeing the smooth procedure of lift systems holds an extremely important significance for both functionality and safety and security. From routine evaluations to resolving usual problems, the precise treatment and attention offered to raise upkeep can significantly affect the long life and efficiency of these vital vertical transport systems. As we check out the subtleties of lift upkeep in this thorough handbook, we will uncover the essential tasks, fix usual issues, and develop security procedures to guard both travelers and the equipment itself. Join us in this expedition of raising your understanding of lift upkeep practices for an effortlessly operational system.

Importance of Lift Maintenance

Guaranteeing regular and comprehensive lift upkeep is critical for the smooth operation, safety and security, and long life of lift systems in structures. Normal upkeep not just maintains the lift running successfully yet also ensures the security of passengers and reduces the risk of unforeseen malfunctions. By adhering to a consistent maintenance schedule, structure owners can recognize and attend to minor concerns prior to they rise into significant issues, ultimately saving time and money in the lengthy run.

In addition to safety and operational effectiveness, correct lift upkeep also plays a significant role in extending the life-span of the lift system. Regular inspections, lubrication of relocating components, and prompt repair work help stop premature deterioration, extending the general long life of the lift. A properly maintained lift not only supplies reliable solution to constructing occupants but also shows positively on the structure's total maintenance criteria.

Important Upkeep Tasks

On a regular basis scheduled upkeep tasks are important for the maintenance of elevator systems in buildings. These jobs guarantee the smooth operation of the lift, extend its life-span, and improve safety for users. One essential upkeep job is routine assessments. Elevator elements must be checked for indicators of deterioration, such as torn wires, loose bolts, or uncommon noises. Lubrication of relocating parts is one more essential job to stop too much friction and wear, which can result in breakdowns. Furthermore, cleaning the lift shaft and cabin helps stop debris from hindering the system's procedure.

Moreover, changing and examining the security functions of the lift, such as emergency brakes and door sensors, is crucial to guarantee they function properly in situation of an emergency. Regularly upgrading software application and firmware for modern lift systems is just as important to stay on top of technical advancements and safety and security procedures. By adhering to these crucial upkeep tasks, building proprietors can ensure their lift systems run successfully and reliably, reducing downtime and pricey repair services.

Common Lift Issues and Solutions

Upkeep tasks play a critical duty in determining and addressing typical lift concerns to ensure the risk-free and smooth operation of elevator systems in structures. One typical trouble is uneven door capability, which can cause hold-ups and safety threats - Lift Maintenance Repair. This problem frequently originates from misaligned door tracks or defective sensors, which can be fixed through regular evaluations and changes throughout upkeep checks

An additional widespread issue is unusual sounds or vibrations throughout procedure. These can indicate problems with the motor, wheel system, or other mechanical elements. Immediately resolving these problems via essential repairs and extensive diagnostics can avoid more damages and guarantee the lift runs quietly and efficiently.

In addition, inconsistent leveling with floors is a constant concern you can try this out that influences passenger convenience and safety. This problem may be caused by misaligned progressing sensors or hydraulic system malfunctions. Regular calibration and maintenance of these parts can correct the problem and enhance the lift's efficiency.

Safety Measures for Lift Upkeep

To promote the integrity and functional safety of lift systems, extensive adherence to developed safety procedures is paramount throughout maintenance treatments. Safety steps for lift upkeep encompass a variety of techniques aimed at mitigating dangers and making certain the wellness of both upkeep personnel and users.

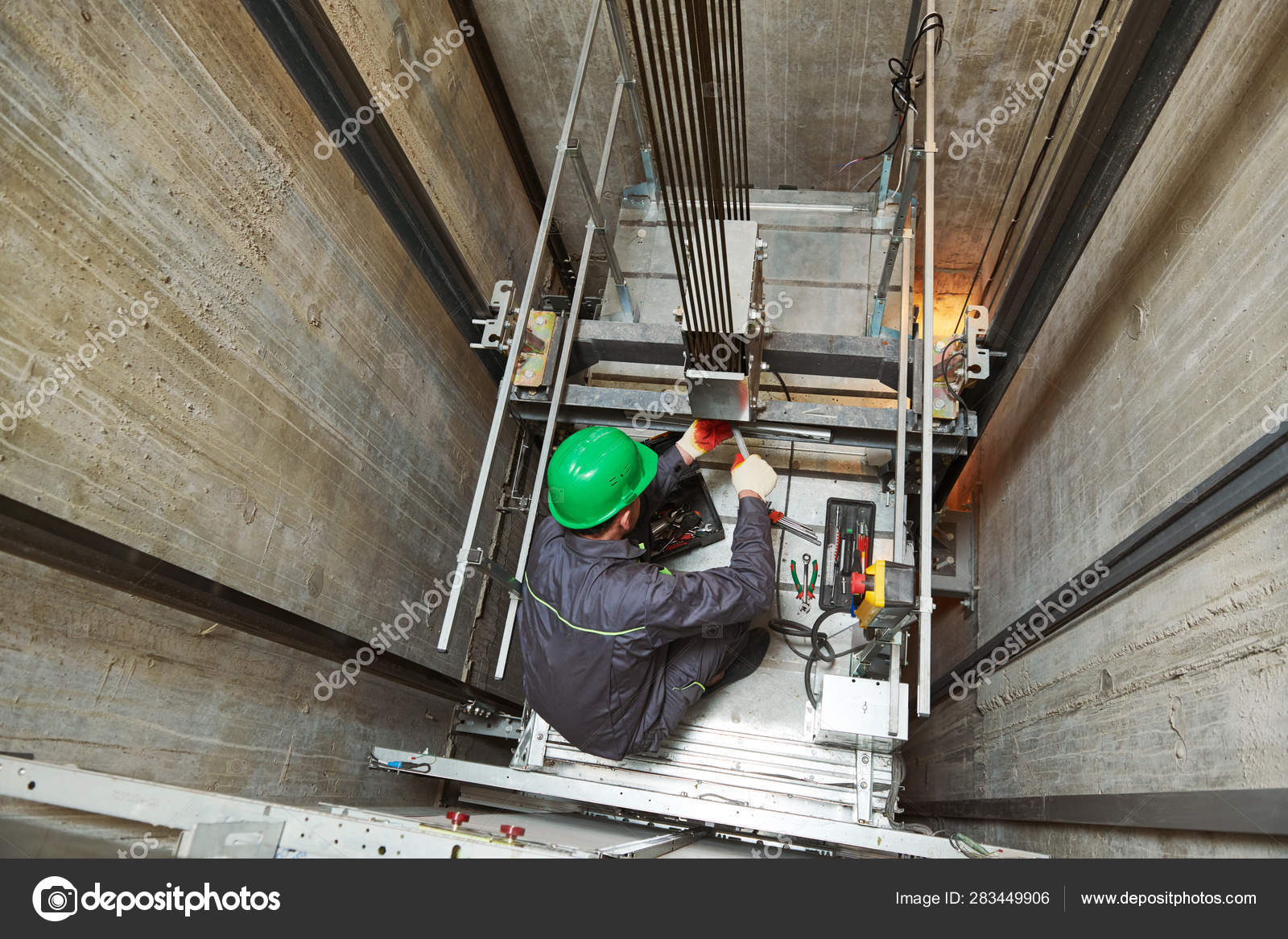

Furthermore, all upkeep employees need to go through comprehensive training on safety procedures and tools procedure to decrease the probability of mishaps. When functioning on or near lift components, personal protective tools such as handwear covers, safety helmets, and safety and security harnesses must be put on at all times. Regular examinations of tools and tools, along with adherence to manufacturer standards, are important to preserving a secure workplace. By prioritizing security measures in lift maintenance practices, the danger of incidents can be substantially reduced, guaranteeing the continued capability and integrity of lift systems.

Advantages of Routine Upkeep

Given the vital focus on safety actions in lift upkeep, comprehending the benefits of normal upkeep is necessary for upholding operational effectiveness and prolonging the lifespan of lift systems. Additionally, normal upkeep adds to set you back financial savings in the long run by avoiding costly repair services and replacements that may occur from neglected upkeep. In general, investing in normal maintenance not only benefits the lift system itself yet additionally boosts the overall individual experience and safety requirements within the building.

Verdict

In final thought, lift upkeep is vital for guaranteeing the secure and efficient procedure of the system. By carrying out important upkeep jobs, addressing usual lift concerns quickly, and adhering to security steps, you can stop costly malfunctions and ensure the durability of your lift system. Regular maintenance not just keeps your lift running smoothly but additionally boosts safety for individuals. Prioritizing lift maintenance is necessary Visit Your URL for the overall performance and integrity of the system.

Safety actions for lift maintenance encompass a variety of methods intended at mitigating dangers and making sure the wellness of both maintenance employees and individuals. By prioritizing safety actions in lift maintenance practices, the risk of incidents can be significantly lowered, ensuring the proceeded functionality my response and integrity of lift systems.

Provided the vital emphasis on safety and security procedures in lift maintenance, recognizing the advantages of normal maintenance is necessary for supporting functional performance and extending the lifespan of lift systems. Furthermore, normal maintenance contributes to set you back savings in the long run by preventing expensive repair services and replacements that might occur from disregarded maintenance. By performing necessary upkeep tasks, attending to usual lift issues immediately, and complying with safety steps, you can avoid costly malfunctions and ensure the longevity of your lift system.

Report this page